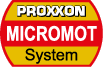

Table saw FET

Extendable table extension with integrated auxiliary stop.

Extendable table extension with integrated auxiliary stop.

Plane-milled table in die-cast aluminium with 2 continuous T-nuts for the angle stop.

Plane-milled table in die-cast aluminium with 2 continuous T-nuts for the angle stop.

Saw blade protection runs up automatically when sawing.

Saw blade protection runs up automatically when sawing.

Clamping screw for height adjustment and pivoting the hard metal-equipped sawblade.

Clamping screw for height adjustment and pivoting the hard metal-equipped sawblade.

Scale helps when adjusting the longitudinal stop!

Scale helps when adjusting the longitudinal stop!

Setting screw for fine adjustment of longitudinal stop by 1/10mm.

Setting screw for fine adjustment of longitudinal stop by 1/10mm.

Angle stop with stop rail of aluminium and adjustable limit stop for manufacturing parts of equal length and the same angle.

Angle stop with stop rail of aluminium and adjustable limit stop for manufacturing parts of equal length and the same angle.

With set-screw for fine adjustment of the longitudinal stop by 1/10mm. Height adjustable tungsten-tipped saw blade, tilting through 45°. For precise, straight cuts without refinishing!

For fine mechanics, model building, mould construction, toy manufacture, architects, model carpenters and fitters.

For cutting wood, non-ferrous metals, plastics, Plexiglas, glass fibre reinforced sheets, foam and many other materials. Stable construction because load bearing parts and plane-milled table are made of die-cast aluminium.

The micro-adjustable, precise and stable longitudinal stop provides decisive advantages: Corrections even smaller than 1/10 mm can be made after coarse adjustment using an adjusting screw. The height adjustable and 45° tiltable saw blade makes it possible to cut double mitres when used together with the angle stop.

Low-noise drive using DC special motor with Optibelt toothed belts. Ball-bearinged saw blade shaft. Tungsten tipped saw blade 80 x 1.6 x 10mm (36 T). Additional work piece pusher and non-slotted ABS sawing gap cover for tight tolerances between saw blade and table.

Technical data:

230V. 7,000rpm. Mitre infinitely adjustable up to 45°. Table size 300 x 300mm. Cutting depth 1 - 22mm. Saw blades between 50 - 85mm can be used (with 10mm centre hole). Weight approx. 6kg.

NO 27 070

Non-slotted sawing cap cover of ABS for tight tolerances between saw blade and table (is slotted from below by the FET saw blade). For cutting very small parts.

Table and drive can be lifted up and supported like an engine bonnet. For cleaning the device and easy saw blade replacement.

- Extendable table extension with integrated auxiliary stop.

- Plane-milled table in die-cast aluminium with 2 continuous T-nuts for the angle stop.

- Saw blade protection runs up automatically when sawing.

- Clamping screw for height adjustment and pivoting the hard metal-equipped sawblade.

- Scale helps when adjusting the longitudinal stop!

- Setting screw for fine adjustment of longitudinal stop by 1/10mm.

- Angle stop with stop rail of aluminium and adjustable limit stop for manufacturing parts of equal length and the same angle.

Use the vacuum cleaner adapter to keep your work area cleaner. We recommend the use of our Automatic workshop vacuum-cleaner WSA.

Saw blades for table saw FET

High-alloy special steel (HSS)

High-alloy special steel (HSS)

Ø 80 x 1.1 x 10mm, 250 teeth. Use on non-ferrous metals, soft and hard woods, laminates, GRP, CFK and composite boards.

NO 28 730

Super cut

Super cut

Ø 85 x 0.5 x 10mm. 80 teeth. Use on hard and soft woods, plastics.

NO 28 731

Tungsten carbide tipped

Tungsten carbide tipped

Ø 80 x 1.6 x 10mm. 36 teeth. Use for balsa, plywood, soft and hard woods, POLYCARBONATE, plastics, non-ferrous metals, glass-fiber reinforced circuit boards.

NO 28 732

Diamond coated

Diamond coated

Ø 85 x 0.7 x 10mm. Layer 'D100'. Ceramics, porcelain, tiles, stone, CFK, CRP and epoxy circuit boards.

NO 28 735