Long and slender spindle neck for working in tough-to-reach areas (including hollow forms).

Long neck straight drill/grinder LBS/E

Head of die-cast aluminium with 75mm long spindle neck (and 20mm MICROMOT collar).

Thus ideal for internal grinding and the use in slots and channels.

Double-row ball bearing. Spindle of ground steel with lock button for rapid cutter changing. Special balanced, powerful, quiet and long-lasting DC motor. Variable (full wave) electronic speed control. Main housing of glass-fibre reinforced POLYAMIDE. MICROMOT collets (1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2mm). Safely stored in an attractive and extremely stable case made from high-grade polypropylene.

Double-row ball bearing. Spindle of ground steel with lock button for rapid cutter changing. Special balanced, powerful, quiet and long-lasting DC motor. Variable (full wave) electronic speed control. Main housing of glass-fibre reinforced POLYAMIDE. MICROMOT collets (1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2mm). Safely stored in an attractive and extremely stable case made from high-grade polypropylene.

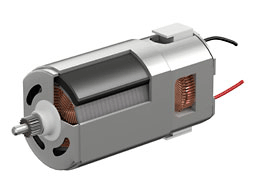

The heart of our MICROMOT precision tools for 230V: the direct current (DC) special motor.

Technical data:

230V. 100W. 5,000 - 22,000/min. Length 300mm. Weight 630g. Insulated to class 2.

NO 28 485

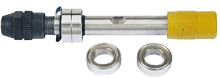

MICROMOT steel collets

As described below. For all handheld MICROMOT machines, excluding the Engraver GG 12. One each 1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2mm, clamping nut and holder for storage are included.

NO 28 940

Note:

MICROMOT steel collets are hardened and thus have a high, consistent flexibility.

MICROMOT steel collets are hardened and thus have a high, consistent flexibility. ![]() They also maintain prolonged accuracy, even after regular use (these collets should not be compared with unhardened, fourslit collets of brass and aluminium). The triple slit collet is substantially more difficult to manufacture than the four-slit type,

They also maintain prolonged accuracy, even after regular use (these collets should not be compared with unhardened, fourslit collets of brass and aluminium). The triple slit collet is substantially more difficult to manufacture than the four-slit type, ![]() but offers a better load-bearing surface.

but offers a better load-bearing surface. ![]() This is especially important for cutters with small shaft diameters.

This is especially important for cutters with small shaft diameters.

Suitable accessories:

Bits and cutters of industrial and dental quality

Bit holder for storing rotating bits and cutters is included in the delivery.

Storage case of high-grade polypropylene. Attractive design, very sturdy and large enough to put the machine back in the case after completing work, without having to "fumble". A label on the side identifies the contents.

A comparatively more expensive direct current (DC) special motor with permanent magnet technology.

A comparatively more expensive direct current (DC) special motor with permanent magnet technology.