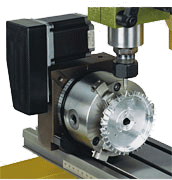

Dividing attachment UT 400/CNC

Dividing attachment UT 400/CNC

4th axis to the PROXXON Miller FF 500/CNC for use with CNC control unit MCS and software NCCAD. For individual parts and small series production. For manufacturing divisions, gear wheels, helical gearings, screw spindles and (including irregular) profiles. All angle positions can be approached by computer control. Easy horizontal and vertical construction. Driven by powerful step motor (2.0A) through toothed belts, and virtually free from play, adjustable worm gear. The high transfer ratio (40:1) provides enormous torque. Main spindle with 14mm drill hole and flange to suit face plates and all lathe chucks from the PD 400 lathe system. Smallest increment 0.003°. Recognition of reference position through light barrier. Not for use with CNC Control CU 4 (NO 24 900). Chuck and work pieces are not included in the package.

NO 24 423

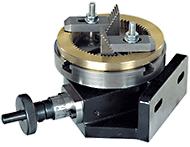

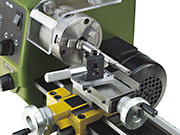

Universal dividing attachment UT 250

Universal dividing attachment UT 250

For fixation on compound table KT 150 and milling machines FF 230 and FF 500/BL. Worm drive for divisions through 360°. Feed adjustment by handwheel with graduated, zero-adjustable dial (1 revolution = 10°). Unit may be fixed horizontally or vertically. For compound tables with distances between T-slots of 45 - 60mm. The flange of the dividing attachment is the same size as that of the main spindle of the PD 250/E lathe, thus 3 jaw chuck (NO 24 034) and 4 jaw chuck (NO 24 036) may be mounted. Incl. faceplate Ø100mm and step clamp set of steel: Two each step blocks and clamps. With matching slot nuts, threaded rods and nuts. Packed in a wooden box.

NO 24 046

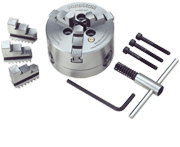

Self-centering 3-jaw chuck

Self-centering 3-jaw chuck

Identical to chuck of lathe PD 250/E. High quality clamping fixture as per DIN 8386, Class 1 (concentricity accuracy 0.04mm). Capacity through reversing jaws from 2 - 75mm. Suitable for PD 250/E and the dividing attachment NO 24 044.

NO 24 034

Radius cutting attachment

Radius cutting attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

NO 24 062

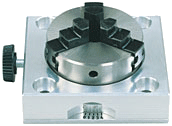

Dividing head for MICRO miller MF 70 and MICRO compound table KT 70

Dividing head for MICRO miller MF 70 and MICRO compound table KT 70

For machining circular work pieces, manufacturing off-set holes and milled out portions, milling key surfaces, four-sided, sixsided materials, etc. Absolute accurate division due to nonius at the base body. With reversed chuck jaws: Capacity inside 1.5 to 32mm, outside 12 to 65mm. Bore of 11mm (for processing longer spindles in a vertical position). With fastening bores for horizontal and vertical mounting and suitable slot nuts and fastening screws for mounting to the MICRO miller MF 70 and the MICRO compound table KT 70. Size 72 x 64 x 38mm. In wooden box with sliding lid.

NO 24 264

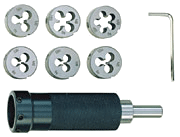

Die holder for round dies

Die holder for round dies

For threads M 3 - 4 - 5 - 6 - 8 and 10.

With holder Ø 10mm for mounting in the tailstock drill chuck of the lathe. The holder is held by hand while cutting the threads. Neatly packed in wooden box with sliding lid.

NO 24 082

Tool holder for rotary tools

Tool holder for rotary tools

Made of steel with standard 20mm MICROMOT collar size.

For precise clamping of rotary tool IBS/E or LBS/E in the tool post of the lathe. Shaft 8 x 10mm. Total length 65mm.

NO 24 098

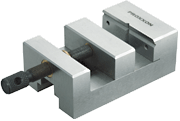

Precision-milled steel machine vices.

Perfectly rectangular. To be placed sideways and on the end face. With matching nuts and screws. Supplied in wooden box with sliding lid.

PM 40

PM 40

Jaw width of 46mm. Clamping capacity 34mm. Total length 70mm.

NO 24 260

PM 60

PM 60

Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

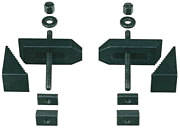

Step clamp set of steel

Step clamp set of steel

2 step blocks and clamps each.

With matching slot nuts and fastening screws for T-slots as per MICROMOT standard (12 x 6 x 5mm). In wooden box with sliding lid.

NO 24 256 For work pieces up to 20mm thickness

NO 24 257 For work pieces up to 35mm thickness

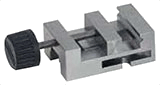

Precision V-blocks

Precision V-blocks

Used to clamp various work pieces.

Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 262 2 pieces

Nearly all accessories are supplied in wooden boxes. For proper and value preserving storage!

Cutting tools of high quality cobalt HSS steel, ground.

HSS boring tool set, 6 pieces

HSS boring tool set, 6 pieces

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm - 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid.

NO 24 520

6-piece turning tool set for precision lathe FD 150/E

6-piece turning tool set for precision lathe FD 150/E

One each boring, roughing out, parting, finishing, right and left cutter. Size 6 x 6 x 65mm. Supplied in wooden box.

NO 24 524

Five piece set

Five piece set

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid.

8 x 8 x 80mm (for PD 230/E and PD 250/E)

NO 24 530

10 x 10 x 80mm (for PD 400)

NO 24 550

Three piece thread cutting set

Three piece thread cutting set

One cutter for external thread ![]() , one for internal thread

, one for internal thread ![]() (both ground to 60°, metric), one general cutting

(both ground to 60°, metric), one general cutting ![]() . Supplied in wooden box with sliding lid.

. Supplied in wooden box with sliding lid.

8 x 8 x 80mm (for PD 230/E and PD 250/E)

NO 24 540

10 x 10 x 80mm (for PD 400)

NO 24 552

Cutter set with tungsten inserts

Cutter set with tungsten inserts

Three holders (90mm long):

![]() for roughing out;

for roughing out;

![]() for longitudinal work;

for longitudinal work;

![]() for 90mm boring bar, holes from 12mm.

for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included.

8 x 8mm (for PD 230/E and PD 250/E)

NO 24 555

10 x 10mm (for PD 400)

NO 24 556

Tungsten disposable tips (not depicted)

For the holders as described above.

NO 24 557Ten piece set

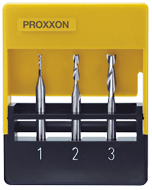

Milling cutter set (2 - 5mm)

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS-Co5. Comes in wooden box with sliding lid.

NO 24 610

Milling cutter set (6 - 10mm)

Milling cutter set (6 - 10mm)

4 cutters Ø 6 - 7 - 8 and 10mm. Four flute design according to DIN 844. Shafts 6 and 10mm respectively. Made of HSS-Co5. Comes in wooden box with sliding lid.

NO 24 620

Tungsten milling cutters

Tungsten milling cutters

With two flute cutters and fishtail profile (cutting to the centre). Enables lowering into non-bored work pieces. For grey-cast iron, hardened cast iron, steel, cast steel, brass, aluminium, glass, plastic and carbon fibre. One piece each 1 - 2 and 3mm. Shaft diameter 3mm.

NO 27 116 3 pieces

Tungsten milling cutters, separately

See description above.

| NO 28 758 | Ø 1mm |

| NO 28 759 | Ø 2mm |

| NO 28 761 | Ø 3mm |

Three piece centre drill set

Three piece centre drill set

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2 - 2.5 and 3.15mm.

NO 24 630

Edge finder set

Edge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

NO 24 434