Performance at its best! The torque makes the difference! The smart alternative with keyless chuck.

- Soft grip for optimal control.

Note:

The FBS 115/E may also be optionally fitted with MICROMOT steel collets.

Soft grip for optimal control.

Soft grip for optimal control.

The Precision Rotary Tool FBS 115/E

With soft grip two-component housing for comfortable handling and optimal control.

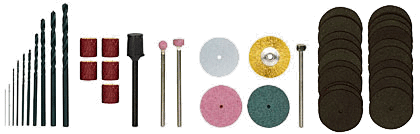

1001 uses for drilling, milling, grinding, polishing, brushing, de-burring, rust removal, engraving, carving and cutting. A special motor technology (no replacing of brushes necessary) with full-wave electronic speed control allows for powerful operation with constant torque, even at low speeds! This feature is especially important when micro-drilling, brushing and polishing on delicate materials (e.g. plastics, etc.).

The extremely balanced motor, which makes the tool run smoothly and vibration-free, as well as low weight and the improved ergonomic design with the soft-grip two-component material allow for optimal control while working. The spindle runs in a precision ball bearing. A button locks the spindle for an easy exchange of bits. The keyless precision chuck allows for quick exchange of all accessories with shanks from Ø 1/64" to Ø 1/8" (0.3 - 3.2mm). The tool’s 4/5" (20mm) standard collar makes it fit easily into all other useful MICROMOT accessories, such as drill stands and vices, making this Precision Rotary Tool even more versatile.

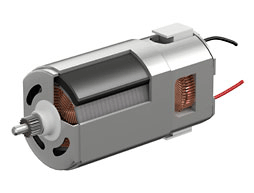

The heart of our MICROMOT precision tools for 115V: the direct current (DC) special motor.

Technical data:

| Speed | 5,000 - 20,000rpm |

| Keyless Chuck | for shanks from 1/64" - 1/8" (0.3 - 3.2mm) |

| Max. Power | 1/8hp (100W) |

| Volts | 110 - 120V AC, 60 Hz |

| Length | 8 1/2" with chuck (220mm) |

| Weight | 1 lb (450g) |

California Residents Prop 65 Information

![]() WARNING:

WARNING:

This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Complete with 43 high-quality bits and cutters in a durable polypropylene case.

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.