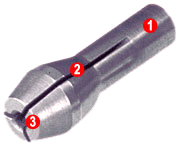

- MICROMOT steel collets are hardened and thus have a high, consistent flexibility. They also maintain prolonged accuracy, even after regular use (these collets should not be compared with unhardened, fourslit collets of brass and aluminium).

- The triple slit collet is substantially more difficult to manufacture than the four-slit type, but offers a better load-bearing surface.

- This is especially important for cutters with small shaft diameters.

MICROMOT steel collets are hardened and thus have a high, consistent flexibility. They also maintain prolonged accuracy, even after regular use (these collets should not be compared with unhardened, fourslit collets of brass and aluminium).

MICROMOT steel collets are hardened and thus have a high, consistent flexibility. They also maintain prolonged accuracy, even after regular use (these collets should not be compared with unhardened, fourslit collets of brass and aluminium).

The triple slit collet is substantially more difficult to manufacture than the four-slit type, but offers a better load-bearing surface.

The triple slit collet is substantially more difficult to manufacture than the four-slit type, but offers a better load-bearing surface.

This is especially important for cutters with small shaft diameters.

This is especially important for cutters with small shaft diameters.

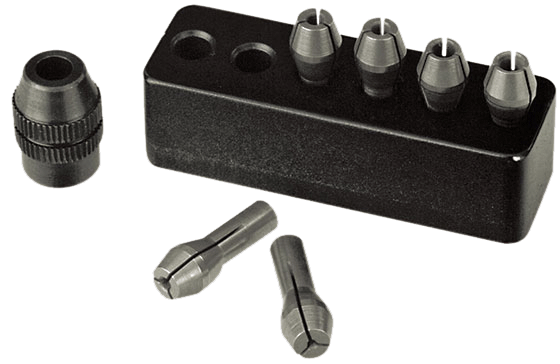

MICROMOT steel collet set

As described on the right. Triple slit and hardened.

1 each of 1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2mm.

With clamping nut and holder for storage.

NO 28 940

Note:

Our drill chuck (NO 28 941) provides more convenience to quickly change the tools when working with shafts of varying diameters (e.g. HSS drills as per DIN 338). However, because of their technical setup, they have a few drawbacks compared to collets: Less clamping force and higher concentricity tolerances. If high precision is necessary, then working with MICROMOT steel collets is a must.