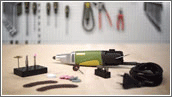

Professional Rotary Tool IBS/E

Usable for extended periods when grinding, polishing, cleaning, cutting and engraving. Ideal for mechanics, model builders, jewelers, opticians, artists and electronic enthusiasts.

Ball bearing spindle of ground steel with lock button for rapid cutter changing.

Ball bearing spindle of ground steel with lock button for rapid cutter changing.

Streamlined head of die cast aluminium for exact bearing seats and optimal stability.

Streamlined head of die cast aluminium for exact bearing seats and optimal stability.

Quiet, powerful 100W motor with full wave electronics for speeds between 5,000 and 20,000rpm.

Quiet, powerful 100W motor with full wave electronics for speeds between 5,000 and 20,000rpm.

Quality without compromise: isolation according to class 2 requirements.

Quality without compromise: isolation according to class 2 requirements.

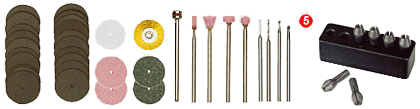

Complete with 34 bits and cutters of industrial quality with shanks of 3/32" (2.3mm) and six steel collets sized 1/32" - 1/8" (1.0 - 3.2mm) as well a a collet nut.

Complete with 34 bits and cutters of industrial quality with shanks of 3/32" (2.3mm) and six steel collets sized 1/32" - 1/8" (1.0 - 3.2mm) as well a a collet nut.

This high-revving motor has full-wave electronic speed control capable of producing variable speeds between 5,000 and 20,000rpm and is usable for extended periods at a time producing an exceptional power/ weight ratio. The streamlined die-cast aluminum head provides a stable housing for the ground steel spindle. It runs in a ball bearing assembly, minimizing play (max. runout 0.001").

The tool comes with six high concentricity collets sized 1/32", 1/16", 5/64", 3/32", 7/64" and 1/8" (1.0, 1.5, 2.0, 2.4, 3.0 and 3.2mm) along with a collet nut as well as a selection of 34 industrial quality bits and cutters with shanks Ø 3/32" (2.3mm).

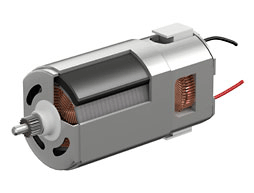

The heart of our MICROMOT precision tools for 115V: the direct current (DC) special motor.

Technical data:

| Speed | 5,000 - 20,000rpm |

| Volts | 110 - 120V AC, 60Hz |

| Max. Power | 1/8hp (100W) |

| Length | 9" (230mm) |

| Weight | 1.1 lb (500g) |

California Residents Prop 65 Information

![]() WARNING:

WARNING:

This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

MICROMOT Steel Collet Set

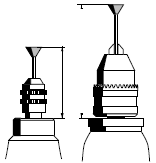

Fits all MICROMOT machines, except the engraver GG 12. One each in size 1/32", 1/16", 5/64", 3/32", 7/64" and 1/8" (1.0, 1.5, 2.0, 2.4, 3.0 and 3.2 mm) come as a set in a practical holder for storage along with one clamping nut.

NO 28 940

NOTE: The collet makes a big difference!

|

MICROMOT steel collets are hardened and have a high, consistent flexibility so that they maintain their accuracy, even if used regularly. |

|

The triple slit collet offers a substantially better load bearing surface than the easier to produce four-slit type. This is especially important for cutters with small shank diameters.

The triple slit collet offers a substantially better load bearing surface than the easier to produce four-slit type. This is especially important for cutters with small shank diameters. |

|

Quality, triple-slit hardened steel collets are ideal for optimum concentricity and tightening force. Furthermore, bits and cutters may be fitted close to the chuck. This is especially important when sanding, routing and milling as side play is minimized.

Quality, triple-slit hardened steel collets are ideal for optimum concentricity and tightening force. Furthermore, bits and cutters may be fitted close to the chuck. This is especially important when sanding, routing and milling as side play is minimized. |

- Ball bearing spindle of ground steel with lock button for rapid cutter changing.

- Streamlined head of die cast aluminium for exact bearing seats and optimal stability.

- Quiet, powerful 100W motor with full wave electronics for speeds between 5,000 and 20,000rpm.

- Quality without compromise: isolation according to class 2 requirements.

- Complete with 34 bits and cutters of industrial quality with shanks of 3/32'' (2.3mm) and six steel collets sized 1/32'' - 1/8'' (1.0 - 3.2mm) as well a a collet nut.

Storage case of high-grade PP. Attractive, extremely stable and large enough to enable the machine to be replaced in it after completion of the work. A label on the side identifies the content.

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.