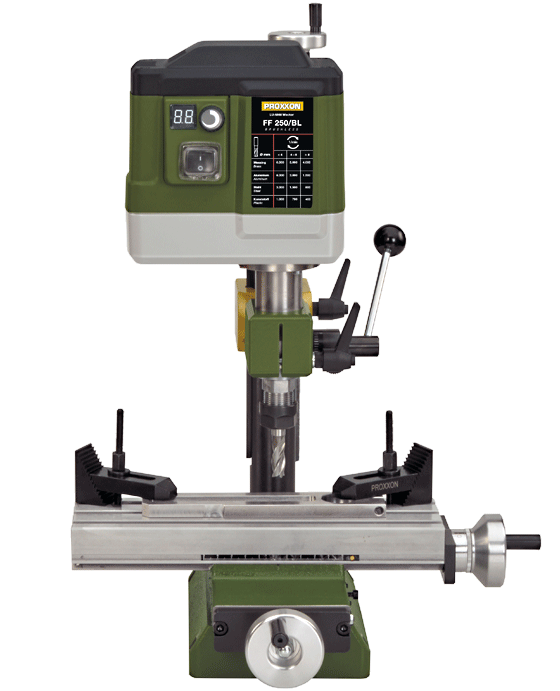

Brushless direct drive. A high accuracy machining system to mill, drill and bore. Made in Germany.

Milling machine FF 250/BL

Variable speed pre-selection from 400 - 6.000rpm. Digital speed indication. The headstock swivels through 360°, indicated on a scale.

230V-operation. The sophisticated control via rotor position and speed sensors guarantees high torque also in the lower speed range. Tool holder using multiple range collets type ER 16 (DIN ISO 15488). One each of 6 - 8 - 10mm are included. Solid plane-milled steel compound table with 3 continuous T-slots.

Technical data:

230V. 250W. 50/60Hz. Spindle speeds 400 - 6.000rpm. Throat 65mm. Stroke 30mm. Column 35 x 400mm. Table 270 x 80mm. X-travel 170mm, Y-travel 65mm. Dimensions 180 x 130mm. Height approx. 500mm. Weight approx. 17kg.

NO 24 114

Note:

Clamping jaws, cutter and work piece are not included in the scope of delivery.

Accessories for the FF 250/BL

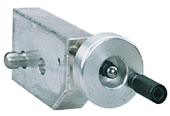

Fine feed for accurate adjustments during milling

Fine feed for accurate adjustments during milling

For FF 250/BL und PF 250/BL. Quick and easy to install. The clutch system enables feed via either the drill handle or the handwheel. The handwheel has 0.025 graduations and may be set to zero. 1 division = 0.05mm.

NO 24 140

Gear tooth chuck (10mm) with adapter

Gear tooth chuck (10mm) with adapter

Industrial quality, however not as accurate as the collets. With 10mm adapter which fits into the 10mm collet. Includes the chuck key.

NO 24 110

Multiple range collet type ER-16 (DIN ISO 15488) (not depicted)

For FF 250/BL and PF 250/BL. One of each Ø 2,4 - 3 - 3,2 - 4 and 5mm. Supplied in a wooden box with sliding lid.

NO 24 146

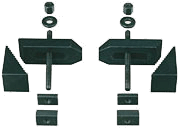

Step clamp set of steel.

Step clamp set of steel.

2 step blocks and clamps each.

With matching slot nuts and fastening screws for T-slots as per MICROMOT standard (12 x 6 x 5mm). In wooden box with sliding lid.

NO 24 256 For work pieces up to 20mm thickness

NO 24 257 For work pieces up to 35mm thickness

Precision V-blocks

Precision V-blocks

Used to clamp various work pieces.

Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 262 2 pieces

Precision vice PM 60

Precision vice PM 60

Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

Three piece centre drill set

Three piece centre drill set

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2 - 2.5 and 3.15mm.

NO 24 630

Milling cutter set (2 - 5mm)

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS-Co5. Supplied in wooden box with sliding lid.

NO 24 610

Milling cutter set (6 - 10mm)

Milling cutter set (6 - 10mm)

4 cutters Ø 6 - 7 - 8 and 10mm. Four flute design according to DIN 844. Shafts 6 and 10mm respectively. Made of HSS-Co5. Supplied in wooden box with sliding lid.

NO 24 620

14-piece parallel supports set

14-piece parallel supports set

Ground in pairs For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 266

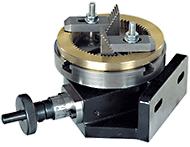

Universal dividing attachment UT 250

Universal dividing attachment UT 250

For fixation on compound table KT 150 and milling machines FF 230 and FF 500/BL. Worm drive for divisions through 360°. Feed adjustment by handwheel with graduated, zero-adjustable dial (1 revolution = 10°). Unit may be fixed horizontally or vertically. For compound tables with distances between T-slots of 45 - 60mm. The flange of the dividing attachment is the same size as that of the main spindle of the PD 250/E lathe, thus 3 jaw chuck (NO 24 034) and 4 jaw chuck (NO 24 036) may be mounted. Incl. faceplate Ø100mm and step clamp set of steel: Two each step blocks and clamps. With matching slot nuts, threaded rods and nuts. Packed in a wooden box.

NO 24 046

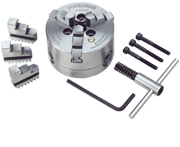

Self-centering 3-jaw chuck

Self-centering 3-jaw chuck

Identical to chuck of lathe PD 250/E. High quality clamping fixture as per DIN 8386, Class 1 (concentricity accuracy 0.04mm). Capacity through reversing jaws from 2 - 75mm. Suitable for PD 250/E and the dividing attachment NO 24 044.

NO 24 034