2-speed scroll saw DS 460

Extremely important: A handy adjusting knob enables sensitive clamping of the saw blades!

Extremely important: A handy adjusting knob enables sensitive clamping of the saw blades!

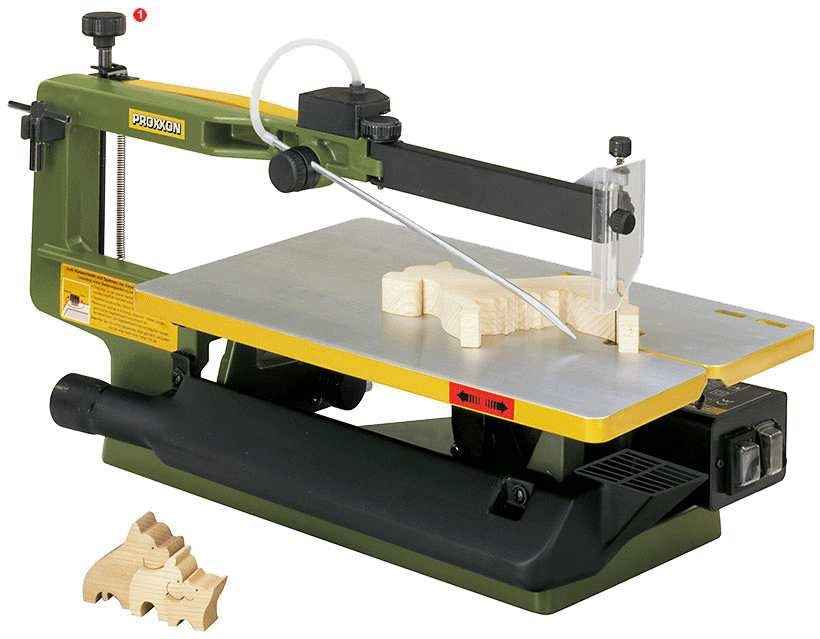

Sturdy construction: Vibration-reducing base housing of cast steel, neatly CNC-processed and powder-coated. For stability and working without vibrations. Extremely light magnesium saw arms reduce the weight of the mass moved by approx. 40% compared to die-cast aluminium. 460mm throat!

Magnesium saw arms precisely mounted on bearings: Extremely light and firm with a slender-shaped cutting area for an unobstructed view of the work piece. Chip blowing device with adjustable nozzle. Additional suction connection to connect a vacuum cleaner.

Large saw table made of die-cast aluminium (400 x 250mm). For easier saw blade replacement, it can be unlocked and pushed back (see description at top right). Regular scroll saw blades are fastened by saw blade holders with high clamping force: This ensures true alignment in the saw arm! The machine has also been prepared for saw blades with pin ends that are used without blade holders. Extremely important for these types of scroll saws: A handy adjusting knob enables sensitive clamping of the saw blades!

Table angle adjustment possible from -5° to 50°.

Cutting performance in wood 60mm, in non-ferrous metals (depending on type) 10 - 15mm. Also easily cuts Plexiglas, glass fibre reinforced plastic, foam, rubber, leather or cork. Includes 5 each coarse and fine saw blades.

Technical data:

230V. Powerful, brushless 2-speed motor (205W). Throat 460mm. Stroke alternatively 900 or 1,400rpm. Saw stroke 18mm. Table size 400 x 250mm. Maximum work piece passage 65mm (at 45° mitre 32mm). L 580mm, W 320mm, H 300mm. Weight 20kg.

NO 27 094

Blade holders for DS 460 (one pair is already included with the machine)

Blade holders for DS 460 (one pair is already included with the machine)

For clamping regular saw blades with high clamping force: for true alignment of the saw arm.

NO 27 096 2 pieces

- Extremely important: A handy adjusting knob enables sensitive clamping of the saw blades!

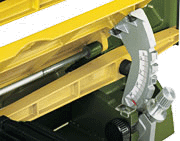

Easy saw blade replacement without tedious fiddling by pushing back the table !

Innovative solution (patented): To enable easy saw blade replacement, the horizontally positioned table can be unlocked and pushed back by 80mm. For an unobstructed view of the bottom saw arm when fitting the saw blade holders or pin end blades.

Patented saw blade holders with high clamping force ensure true alignment of the saw blades. Recesses in the table surface serve as guide line in assembly to define position and distance of the saw blade holders.

Table angle adjustment possible from -5° to 50°. With large dimensioned serrations at 0°, 10°, 20°, 30° and 45°. Additional fine adjustment for precise mitre and angle cuts.

Note:

When cutting extremely hard work pieces (iron), the toothing in the contact area becomes worn relatively quickly. The upper part of the blade toothing can be used by increasing the work piece support surface.

Use the vacuum cleaner adapter to keep your work area cleaner. We recommend the use of our Automatic workshop vacuum-cleaner WSA.

Even the best machine's performance is limited, if saw blades of mediocre quality are used! Play it safe with PROXXON quality saw blades:

"Super-Cut" scroll saw blades without pins. 130mm.

For cutting hard and soft woods, plastic, Perspex.

| Coarse-toothed blades | (No. 9: 13 teeth per 25mm) | |

| NO 28 116 | 130 x 1.3 x 0.44mm | 12 pieces |

| Standard-toothed blades | (No. 5: 17 teeth per 25mm) | |

| NO 28 117 | 130 x 1.02 x 0.36mm | 12 pieces |

| Fine-toothed blades | (No. 3: 19 teeth per 25 mm) | |

| NO 28 118 | 130 x 0.85 x 0.32mm | 12 pieces |

Hard materials such as steel and PERTINAX.

| Standard-toothed blades | (No. 5: 35 teeth per 25mm) | |

| NO 28 112 | 130 x 0.85 x 0.4mm | 12 pieces |

| Fine-toothed blades | (No. 3: 40 teeth per 25mm) | |

| NO 28 113 | 130 x 0.75 x 0.36mm | 12 pieces |

| Very fine-toothed blades | (No. 1: 47 teeth per 25mm) | |

| NO 28 114 | 130 x 0.63 x 0.3mm | 12 pieces |

Spiral blade. 130mm long with plain ends (without pins).

These blades cut all directions and obviate the turning of the workpiece (advantageous, especially with bigger workpieces). A 1.5mm hole is required. Ideal for plastic, hard and soft woods.

| NO 28 747 | 1.1 mm | 12 pieces |

Professional scroll saw blades with reversed toothing.

For clean cuts without tears at the workpiece bottom. For hard- and soft woods.

| Without pin. Coarse-toothed. 11 teeth per 25mm | ||

| NO 28 119 | 130 x 1.02 x 0.36mm | 12 pieces |

| With pin. Standard-toothed, 14 teeth per 25mm | ||

| NO 28 749 | 130 x 1.85 x 0.5mm | 12 pieces |

Standard scroll saw blades with pin ends. 127mm.

| For cutting soft and hard wood, plastics as well as other soft materials and especially thicker work pieces. | ||

| Coarse-toothed | (10 TPI per 25mm) | |

| NO 28 741 | 127 x 3 x 0.5mm | 12 pieces |

| For cutting thin materials, soft and hard wood as well as plastics. | ||

| Normal toothed | (18 TPI per 25mm) | |

| NO 28 743 | 127 x 2.28 x 0.5mm | 12 pieces |

| For cutting non-ferrous metals, glass-fibre reinforced plastics, plastics, Plexiglas and wood. | ||

| Fine-toothed | (25 TPI per 25mm) | |

| NO 28 745 | 127 x 2 x 0.25mm | 12 pieces |