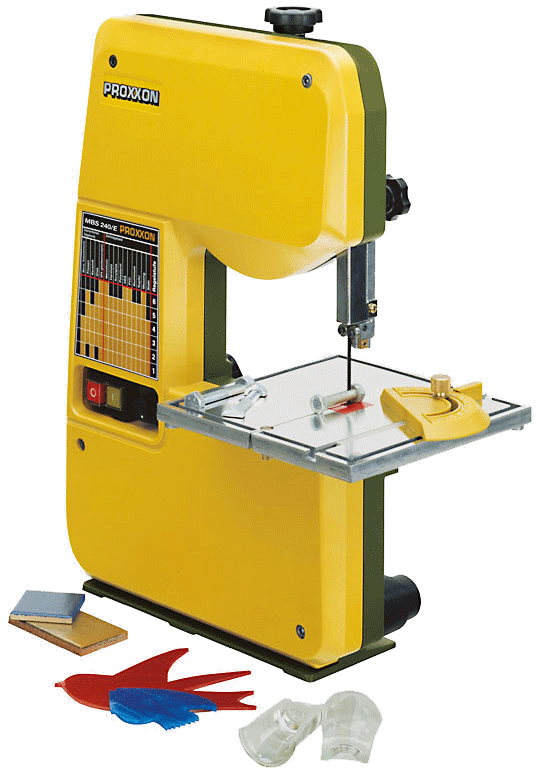

Perfect cuts in steel, non-ferrous metals, wood and plastic. With triple ball bearing blade guide.

MICRO bandsaw MBS 240/E

Use the vacuum cleaner adapter to keep your work area cleaner. We recommend the use of our Automatic workshop vacuum-cleaner WSA.

MICRO bandsaw MBS 240/E

Solid, ribbed die-cast aluminium housing (no tubular or sheet metal construction).

Double ball bearing mounted aluminium pulleys. Sturdy, plane-milled table with slot for mitre gauge (tilts through 45° for accurate mitre sawing). Triple ball bearing blade guide system, adjustable in height and width for different widths of saw blades. Low noise 220V motor (high quality, for quiet, prolonged use) with Optibelt toothed belt.

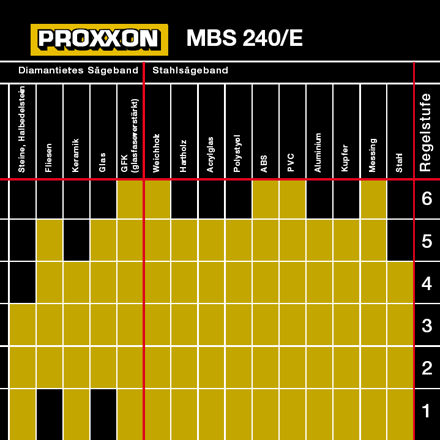

Electronically controlled speed for exceptionally accurate cutting (no subsequent finishing necessary !). A table indicates the recommended speed for practically all kinds of material. The blade size of 5 x 0.4mm is ideal for fine work and allows for cutting of small radii.

Technical data:

230V. Blade speed adjustment from 180 to 330m/min (feedback effect). Throat 150mm, maximum height 80mm. Table 200 x 200mm (tiltable from 0° to 45°). Weight approx. 8kg. One blade 1,065 x 5 x 0.4mm (14 TPI) is included.

NO 27 172

Use the vacuum cleaner adapter to keep your work area cleaner. We recommend the use of our Automatic workshop vacuum-cleaner WSA.

Accessories for the MICRO bandsaw MBS 240/E

TPI stands for the number of teeth per inch (25mm) per bandsaw blade.

Blade guide, separately

Blade guide, separately

NO 28 187

Standard bandsaw blade

Of hardened Swedish steel. Fine-toothed (24 TPI). For steel and brass.

NO 28 174 1,065 x 5 x 0.4mm

As above,

but coarse toothed (14 TPI). Ideal for cuts in wood.

NO 28 176 1,065 x 5 x 0.4mm

Extra narrow bandsaw blade (3.5mm) for tight radii

Of special tempered steel, with induction-hardened coarse teeth (14 TPI). Especially suited for aluminium and plastics.

NO 28 180 1,065 x 3.5 x 0.5mm

Bandsaw blade of bimetal

Bandsaw blade of bimetal

Carrier belt of alloyed tempering steel, sawing teeth of wear-resistant high-speed steel. Varying teeth 10 - 14 TPI. Ideal for cutting all standard steel qualities, non-ferrous metals and stainless steel.

NO 28 172 1,065 x 6 x 0.6mm

- HSS flat wire

- Carrier belt of alloyed tempering steel

- Special welding process

HSS flat wire

HSS flat wire

Carrier belt of alloyed tempering steel

Carrier belt of alloyed tempering steel

Special welding process

Special welding process

Diamond blade

For cutting stone, ceramics, glass or glass-fibre reinforced plastics. Only proper cooling of the diamond band will ensure optimally cut glass or ceramics and enable a long service life of the band. Sparingly coolant liquid can be applied with a brush.

NO 28 186 1,065 x 3 x 0.3mm