NOTE: The collet makes a big difference!

- MICROMOT steel collets are hardened and have a high, consistent flexibility so that they maintain their accuracy, even if used regularly.

- The triple slit collet offers a substantially better load bearing surface than the easier to produce four-slit type. This is especially important for cutters with small shank diameters.

MICROMOT steel collets are hardened and have a high, consistent flexibility so that they maintain their accuracy, even if used regularly.

MICROMOT steel collets are hardened and have a high, consistent flexibility so that they maintain their accuracy, even if used regularly.

The triple slit collet offers a substantially better load bearing surface than the easier to produce four-slit type. This is especially important for cutters with small shank diameters.

The triple slit collet offers a substantially better load bearing surface than the easier to produce four-slit type. This is especially important for cutters with small shank diameters.

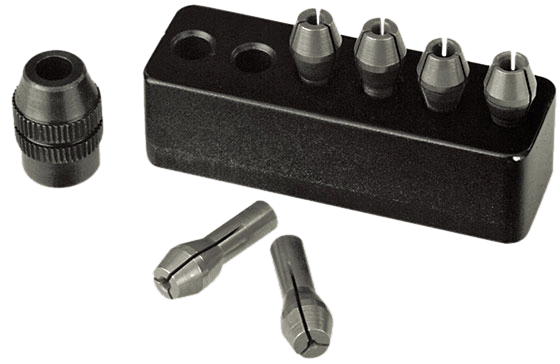

MICROMOT Steel Collet Set

Fits all MICROMOT machines, except the engraver GG 12. One each in size 1/32", 1/16", 5/64", 3/32", 7/64" and 1/8" (1.0, 1.5, 2.0, 2.4, 3.0 and 3.2 mm) come as a set in a practical holder for storage along with one clamping nut.

NO 28 940

California Residents Prop 65 Information

![]() WARNING:

WARNING:

This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Note:

Our drill chuck (NO 28 941) provides more convenience to quickly change the tools when working with shafts of varying diameters (e.g. HSS drills as per DIN 338). However, because of their technical setup, they have a few drawbacks compared to collets: Less clamping force and higher concentricity tolerances. If high precision is necessary, then working with MICROMOT steel collets is a must.