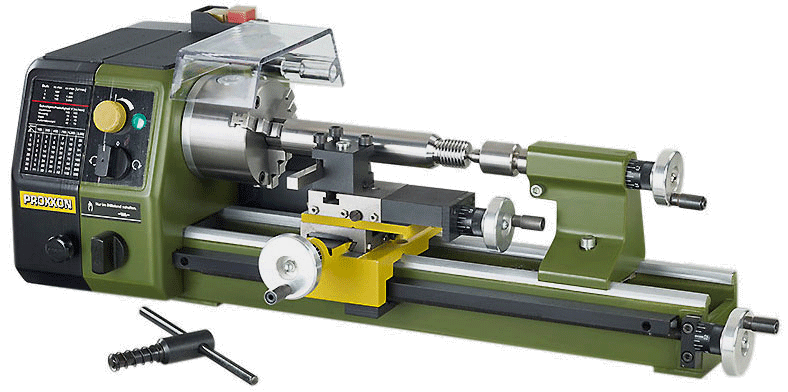

Precision lathe PD 250/E

For face, longitudinal and taper turning, thread-cutting. For machining steel, brass, aluminium and plastic. Mounting flange for fastening the mill/drill head PF 230. Centre distance 250mm (10"). Swing 70mm (2 3/4"). Height over cross slide 43mm (1 11/16").

Machine bed: Of cast iron, wide-legged prismatic guide. For vibration-free work even at high loads. Rear flange for mounting the mill/drill head PF 230. Covered lead spindle.

Headstock: Of die-cast aluminium. Precision bearing mounted main spindle (run-out without chuck 1/100mm (0.0004")) with 10.5mm (13/32") opening. Chuck side 70mm (2 3/4") hollowed to 14mm (0.56"). With MT 2 bore. Rotary switch for engaging the automatic feed via lead and feed spindle (optionally 0.05 or 0.1mm/rev. (2/100" or 4/1000")).

Tailstock: Of die-cast aluminium. Sleeve Ø 20mm (3/4"), retractable up to 30mm. With millimetre scale, MT 1 bore and live centre.

Support: Bed carriage made of die-cast zinc. Cross slide and top slide of steel (adjustment 60 or 45mm (2 3/8" or 1 3/16")). Turning tool post for cutting tools size 8 x 8mm (5/16" x 5/16").

Drive: Quiet DC special motor with 3-stage belt drive for 300 - 900 and 3,000rpm. With additional speed control (full-wave electronics) continuously adjustable to 100 - 300 or 1,000rpm, depending on belt ratio. Clockwise - anticlockwise rotation. Main switch with emergency stop function and restart protection.

Lathe chuck: High quality 3-jaw chuck as per DIN 8386 Class 1 (concentricity tolerance 0.04mm (0.002")). Capacity through reversing jaws from 2 - 75mm (5/64" - 3"). Including lathe chuck guard with safety shutdown.

Handwheels: Of aluminium, with adjustable scale ring (1 division = 0.05mm (.002"), 1 revolution = 1mm (3/64")).

Thread cutting device: With change gears for left-hand and righthand threads of the most important metric pitches (0.5 - 0.625 - 0.7 - 0.75 - 0.8 - 1 - 1.25 - 1.5mm).

Other technical data: 110 - 120V. 50/60Hz. Size L 560mm (22") W 270mm (10 3/4"), H 170mm (6 5/8"). Weight approx. 12kg.

NO 34 002

California Residents Prop 65 Information

![]() WARNING:

WARNING:

This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Accessories for the PD 250/E

Radius Cutting Attachment

Radius Cutting Attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres up to max. 32mm. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Complete with finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid.

NO 24 062

![]() Quick change tool post - easy to use!

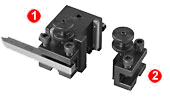

Quick change tool post - easy to use!

For quick tool change and easy height adjustment. Includes 2 tool holder elements.

NO 24 026

![]() Additional quick change tool holder (separately)

Additional quick change tool holder (separately)

Can be used with the above above-mentioned quick change tool post.

NO 24 024

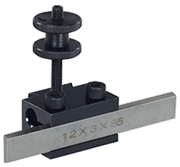

Parting tool holder and tool

Used in the PD 250/E quick change system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt. Spare tools available under NO 24 554, see below.

NO 24 217

Spare tool for parting tool holder (not depicted)

Cutter 12 x 3 x 85mm. As described above.

NO 24 554

Splash guard and chip collecting tray

Splash guard and chip collecting tray

Made from 1.5mm (1/16") thick sheet metal, powder coated. Bevelled edges at the front and back allow slight cleaning. Mounting hole and raised base to secure lathe are pre-drilled. The depicted lathe is not included in the offer.

NO 24 008

4-jaw chuck with independent jaws

4-jaw chuck with independent jaws

For clamping angular and asymmetrically shaped work pieces. Capacity up to 80mm (3,1"). Chuck Ø 75mm (3").

NO 24 036

Collet set with ER 20 collets: For extreme true concentric accuracy. 2 - 10mm (5/64" - 25/64").

Collet set with ER 20 collets: For extreme true concentric accuracy. 2 - 10mm (5/64" - 25/64").

For high precision machining of round parts. The collet set is mounted instead of the lathe chuck. With 8 collets (2 - 2.5 - 3 - 4 - 5 - 6 - 8 and 10mm). Packed in a wooden box.

NO 24 038

Centre turning attachment. For highest accuracy with high rotational precision.

Centre turning attachment. For highest accuracy with high rotational precision.

This includes: 1 face plate, 2 fixed centres (MT 2 and MT 1/short) and 1 drive dog. Packed in a wooden box.

NO 24 014

Fixed steady for longer work pieces

Fixed steady for longer work pieces

Especially for boring. Also required if the tailstock cannot be used to "counter". Up to Ø 40mm.

NO 24 010

Professional gear chuck with MT1

Professional gear chuck with MT1

For the tailstock of the PD 250/E. Capacity up to 10mm (3/8").

NO 24 020

Self-centering 3-jaw chuck

Self-centering 3-jaw chuck

Identical to chuck of lathe PD 250/E. High quality clamping fixture as per DIN 8386, Class 1 (concentricity accuracy 0.04mm). Capacity through reversing jaws from 2 - 75mm. Suitable for PD 250/E and the dividing attachment NO 24 044.

NO 24 034

Five Piece Cutting Set

Five Piece Cutting Set

8 x 8 x 80mm

(5/16" x 5/16" x 3 9/64").

One each roughing out, parting, finishing cut, left and right cutter. Made from high-quality Cobalt HSS, pre-ground. Packaged in a wooden box.

NO 24 530

Three Piece Thread Cutting Set

Three Piece Thread Cutting Set

6 x 8 x 80mm

(15/64" x 5/16" x 3 9/64").

One cutter for external thread (ground to 60°, metric) ![]() , one for internal thread

, one for internal thread ![]() , one general cutting

, one general cutting ![]() . Made from high-quality Cobalt HSS, pre-ground. Packaged in a wooden box.

. Made from high-quality Cobalt HSS, pre-ground. Packaged in a wooden box.

NO 24 540

Cutter Set with tungsten inserts

Cutter Set with tungsten inserts

Three holders (5/16" x 5/16" x 3 35/64"), for roughing out ![]() , finishing cuts

, finishing cuts ![]() and boring bar

and boring bar ![]() , holes from 15/32". Standard tungsten tips, 55°, plated. Three additional inserts, securing screws and key TX8 are included.

, holes from 15/32". Standard tungsten tips, 55°, plated. Three additional inserts, securing screws and key TX8 are included.

NO 24 5558 x 8mm

Tungsten Disposable Tips

Tungsten Disposable Tips

for the holders 24 555. Ten piece set.

NO 24 557

Three Piece Center Drill Set

Three Piece Center Drill Set

HSS, 60°. Complete set with sizes of 2, 2.5 and 3.15mm (5/64", 3/32", 1/8"). Made from high-quality Cobalt HSS, pre-ground. Packaged in a wooden box.

NO 24 630

HSS Boring Tool Set

HSS Boring Tool Set

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 2.5mm, 3mm and 4mm. Shank: 6mm (15/64"). Length: 95 mm (3 3/4"). The cutters are held by a tool holder that mounts to the tool post of the PD 250/E. Comes in a wooden box.

NO 24 5206 pieces

Tool Holder for rotary tools. For use on lathe machines.

Tool Holder for rotary tools. For use on lathe machines.

This holder allows mounting of our rotary tool IBS/E (collar size 20mm (4/5")) to the tool post of the Lathe PD 250/E for grinding or polishing purposes.

NO 24 098

Die Holder for round dies, threads M 3 to M 10

Die Holder for round dies, threads M 3 to M 10

Sizes: M 3 - 4 - 5 - 6 - 8 - 10. The straight shank 13/32" fits our drill chuck NO 24 020 when mounted in the tailstock of the PD 250/E. The holder is held by hand while cutting the threads. Comes in a wooden box.

NO 24 082

14-piece parallel supports set

14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.002mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 2666 pieces

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.

In relation to its size, the permanent magnet technology makes it very powerful, quiet and long-lasting. Due to its very high efficiency, this motor requires considerably less power for the same power output from the socket outlet than other commonly used motors.