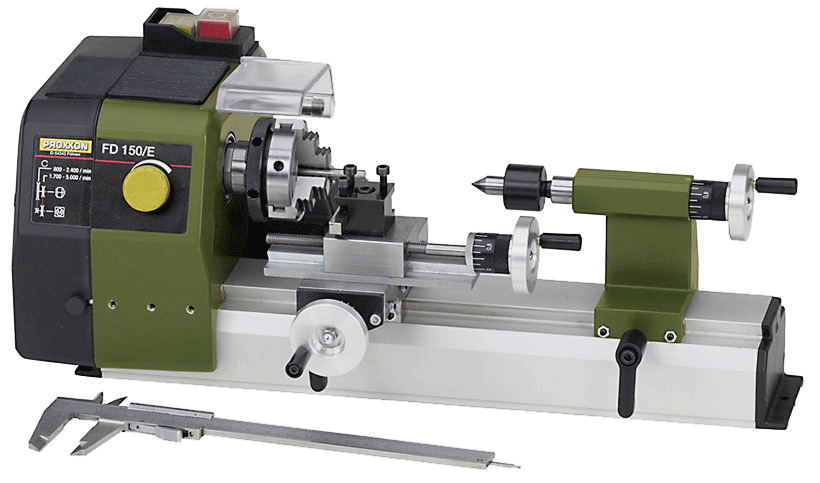

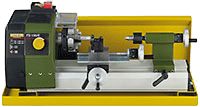

Precision lathe FD 150/E

2-stage belt drive and additional electronic control enables spindle speeds up to 5,000rpm. The right cutting speed for even the smallest pieces. For face turning, longitudinal turning, boring, taper turning, slicing and drilling. Complete with 3-jaw chuck and live center. Center distance 150mm (6"). Swing 55mm (2.2"). Height over cross slide 33mm (1.3").

Machine bed with dovetail guides of continuous aluminium casting.

Die-cast aluminum spindle headstock. With quiet special DC motor, 2-stage belt drive and additional electronic speed control for high torque at low speeds for larger work pieces and for the appropriate cutting speed, even for the smallest pieces. Main switch with emergency stop function and restart protection. Precision bearing mounted main spindle with continuous 8.5mm (21/64") bore. Chuck fit for standard ER 11 type collets.

Three-jaw chuck, self-centering (inside jaws 1 - 20mm (1/32" - 4/5"), outside jaws 20 - 50mm (4/5" - 2")).

Die-cast aluminum tailstock with spindle and live center (fitting MK 0/short).

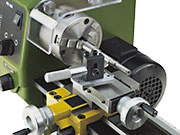

Support: To be shifted manually on the bed and clamped with lever. Rotating tool post for turning steels 6 x 6mm (15/64" x 15/64"). Processing via top slide (60mm (2.35"), travel distance Z) and cross slide (40mm / 1.57"), travel distance X). The angle adjustment of the upper carriage makes it possible to turn tapers up to +/- 45°.

Handwheels withwith zero adjustable scale ring (1 division = 0.05mm (0.002"), 1 revolution = 1mm (1/32")).

Other technical data:

110 - 120V AC. 50/60Hz. Distance between centers 150mm (6"). Swing 55mm (2.2"). Height over cross slide 33mm (1.3"). Cross slide travel (X) 40mm (1.57"), top slide travel (Z) 60mm (2.35"). Steel tool post for turning steels 6 x 6mm (15/64" x 15/64"). Spindle bore 8.5mm (21/64"). 2-stage belt drive with electronic speed control: Stage 1 = 800 - 2,800rpm. Stage 2 = 1,500 - 5,000rpm. Dimensions approx. 360 x 150 x 150mm. (14.1" x 6" x 6"). Weight 4.5kg (10 lbs).

NO 34 150

Accessories for the FD 150/E

Radius cutting attachment

Radius cutting attachment

For working on convex and concave shapes. Can be mounted on the cross slide instead of the tool holder. Enables turning of radii or 3/4 balls up to max. 32mm (1 1/4") in steel (max. cutting depth 1mm (1/32"), non-ferrous metals and plastics. Comes with one finishing cutter 8 x 8mm (5/16"x 5/16") in a wooden box.

NO 24 062

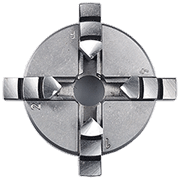

4-jaw-chuck, self-centering

4-jaw-chuck, self-centering

Used to clamp cylindrical, square, or octagonal work pieces. High accuracy. Clamping range with reversible jaws from 1 - 20mm (inside) and 20 - 50mm (outside). Ø 50mm.

NO 24 158

Chip collecting tray with splash guard for the FD 150/E

Chip collecting tray with splash guard for the FD 150/E

Of 1.5mm (1/16") thick sheet steel, powder-coated. Bevelled edges at the front and back enable easy cleaning. Pre-drilled mounting holes for the secure stability of the FD 150/E. L 400 x W 165 x H 140mm (L 15 3/4" x W 6.5" x H 5.5"). The lathe depicted here is not included in the scope of delivery.

NO 24 156

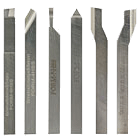

6-piece turning tool set. Made of high-quality cobalt HSS steel. Ground.

6-piece turning tool set. Made of high-quality cobalt HSS steel. Ground.

One each boring, roughing out, parting, finishing, right and left cutter. Size 6 x 6 x 65mm (15/64" x 15/64" x 2 1/2". For FD 150/E, supplied in wooden box.

NO 24 524

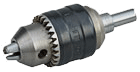

Drill chuck. Capacity 0.5 - 6.5mm (1/64" - 1/4").

Drill chuck. Capacity 0.5 - 6.5mm (1/64" - 1/4").

Industrial quality with high concentricity (allowed up to 10,000rpm). Complete with arbour B 10 x MK 0/short. For the tailstock of the FD 150/E.

NO 24 152

Multiple range standard ER 11 type collets

Multiple range standard ER 11 type collets

Offering high concentricity. May be reduced up to 0.5mm below their nominal diameter (intermediate sizes not required). D = 11.5mm, L = 18mm. One each of 2. - 2.5 - 3 - 4 - 5 - 6 and 7mm are included. With clamping nut M 16 x 1. Suitable for the main spindle of the FD 150/E. Supplied in a wooden box.

NO 24 1547 pieces