Flexibility in cutting styrofoam board. No "crumbling" as when working with a knife or saw.

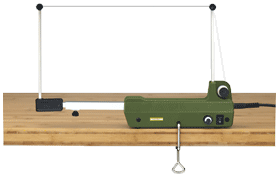

Hot Wire Cutter THERMOCUT 650

Flat support surface and lateral bore with the included c-clamp allow stationary use.

Flat support surface and lateral bore with the included c-clamp allow stationary use.

Telescopic arm for adjustable cutting lengths from 400 - 650mm (15 3/4" - 25 1/2"). Cutting depth (throat capacity) 200mm (7.9").

Telescopic arm for adjustable cutting lengths from 400 - 650mm (15 3/4" - 25 1/2"). Cutting depth (throat capacity) 200mm (7.9").

Spring element in support bracket ensuring constant wire tension regardless of temperature based wire expansion.

Spring element in support bracket ensuring constant wire tension regardless of temperature based wire expansion.

For architects, designers, artists, in prototype construction, insulation work and for classic model building (railroads, airplanes, boats).

For cutting styrofoam, hard foam, polyurethane, PU foam and thermoplastic materials. 110 - 120V AC connection with a 95" power cord. The heating element is operated with a safety voltage of max. 40V and 1.2A. Depending on the material, the cutting wire temperature is pre-selected using the practical control knob and remains stable while working. Supporting surface with lateral bore for fixing a c-clamp to allow for stationary use. A c-clamp and a spool with 30m (98ft) of cutting wire 0.2mm are included in the scope of delivery.

Technical data:

110 - 120V. AC 50/60Hz. 50W. Secondary voltage max. 40V, 1.2A. Cutting temperature of wire 0.2mm (0.008") continuously variable from 100 - 350 °C (210 - 660 °F). Weight 850g (1.9 lbs). Insulated to Class 2.

NO 37 084

California Residents Prop 65 Information

![]() WARNING:

WARNING:

This product can expose you to chemicals including lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Spare Cutting Wire for Hot Wire Cutter THERMOCUT 650

Spare Cutting Wire for Hot Wire Cutter THERMOCUT 650

Made of NiCr 8020. Spool diameter Ø 15/16" (24mm). Spool thickness 5/16" (8mm). Bore diameter Ø 1/4" (6.5mm). Wire size Ø 0.008" x 98ft (Ø 0.2mm x 30m).

NO 28 080

Footswitch FS

Footswitch FS

This attachment frees your hands for easy on/off operation. To be used for all machines with a maximum power consumption of 5/8hp (500W) with two prong plugs. The switch has a housing of glass-fiber-reinforced nylon. The connecting cord is 3ft. 21" (250cm) in length and the output cord is 19.5" (50cm). Ideal for both portable and stationary machines.

NO 38 700

- Flat support surface and lateral bore with the included c-clamp allow stationary use.

- Telescopic arm for adjustable cutting lengths from 400 - 650mm (15 3/4" - 25 1/2"). Cutting depth (throat capacity) 200mm (7.9").

- Spring element in support bracket ensuring constant wire tension regardless of temperature based wire expansion.

Note:

For cutting styrofoam or hard foam hot wire cutters are vastly superior to other tools such as knives or saws. Most important is to select the right temperature depending on material and thickness. With a bit of patience and practice anyone can do this! Most precise cutting results are usually achieved at medium temperatures and moderate pressure.

Flat support surface and lateral bore to fix a screw clamp allow also stationary use. Practical when cutting standard styrofoam boards (100 x 50cm).

Flat support surface and lateral bore to fix a screw clamp allow also stationary use. Practical when cutting standard styrofoam boards (100 x 50cm).