36-piece Precision engineer's bit set with 1/4''-MICRO bit ratchet.

- 9 bits in extra long version (80mm).

- 25 bits in standard lenght (25mm).

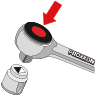

- MICRO bit ratchet. 72 teeth. With extremely slim head (23 x 12mm).

No bit-adapter necessary!

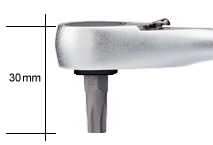

1/4''-MICRO bit ratchet for hexagonal bits. With magnetic insert. Distance between reverse lever and bit end only 30mm. Fine tooth drive: Several of the 72 teeth engage simultaneously for transmitting high torque. Reverse lever for ratcheting direction. Made from CrV steel, double nickel plated with matt chrome plated finish. Grip of oil and acid-resistant TPR (Thermoplastic Rubber). Total length 120mm.

1/4''-MICRO bit ratchet for hexagonal bits. With magnetic insert. Distance between reverse lever and bit end only 30mm. Fine tooth drive: Several of the 72 teeth engage simultaneously for transmitting high torque. Reverse lever for ratcheting direction. Made from CrV steel, double nickel plated with matt chrome plated finish. Grip of oil and acid-resistant TPR (Thermoplastic Rubber). Total length 120mm.

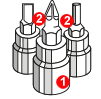

Bits of industrial quality, accurate and wear resistant. Made of special chrome-molybdenum-silicon-manganese-vanadium steel alloy. Hardened according to latest production standards.

| 25mm | 80mm | |||

| TTX | 8 - 9 - 10 - 15 - 20 - 25 - 27 - 30 - 40 | 10 - 15 - 20 - 25 - 30 | ||

| HX | 2 - 2,5 - 3 - 4 - 5 - 6 - 8 | 3 - 4 - 5 | ||

| XZN | 5 - 6 - 8 | |||

| PH | 0 - 1 - 2 | 1 | ||

| PZ | 1 - 2 | |||

| SL | 3.5 |

In addition, magnetic holder for work with electric screwdriver or drill. All parts are clearly marked. In sturdy steel box (powder-coated).

NO 23 109

Also available individually:

1/4''-MICRO bit ratchet

- 9 bits in extra long version (80mm).

- 25 bits in standard lenght (25mm).

- MICRO bit ratchet. 72 teeth. With extremely slim head (23 x 12mm).

Quality at its best:

Highest quality, exceeds DIN/ISO requirements for hardness and maximum torque. Individual size tolerances are all well within the prescribed norms.

The ratchet - the key item:

The ratchet - the key item: The PROXXON driver system:

The PROXXON driver system: Screwdriver bits:

Screwdriver bits: