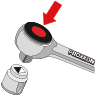

Fine-toothed with extremely slim ratchet head. Reduced length for tricky work, where space is tight.

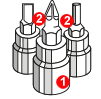

MICRO compact ratchets 1/4" (6.3mm), 3/8" (10mm) and 1/2" (12.5mm)

Several of the 72 teeth engage simultaneously transferring extremely high torques. Reverse lever for ratcheting direction. Release mechanism: unlocking the sockets at the push of a button. Forged from CrV-steel, double nickel plated with matt chrome plated finish. Grip of oil- and acid-resistant TPR (Thermoplastic Rubber) with practical hole for hanging up.

MICRO compact ratchet, 1/4"-square drive (6.3mm)

NO 23 160![]() (12 x 23mm) overall length of 120mm

(12 x 23mm) overall length of 120mm

MICRO compact ratchet, 3/8"-square drive (10mm)

NO 23 162![]() (15 x 28mm) overall length of 150mm

(15 x 28mm) overall length of 150mm

MICRO compact ratchet, 1/2"-square drive (12.5mm)

NO 23 164![]() (17 x 34mm) overall length of 195mm

(17 x 34mm) overall length of 195mm

Note:

Only 3/8"- and 1/2"-versions are new. The 1/4"-model was already introduced in 2018. It is again shown here to complete the range.

![]()

For full

professional use!

The ratchet - the key item:

The ratchet - the key item: The PROXXON driver system:

The PROXXON driver system: Screwdriver bits:

Screwdriver bits: