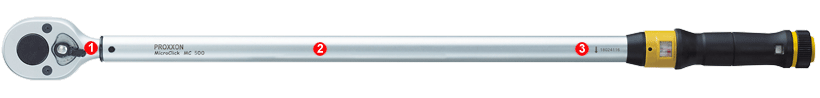

MicroClick MC 500.

For 100 - 500Nm.

Reverse lever for clockwise and anticlockwise rotation.

Reverse lever for clockwise and anticlockwise rotation.

Sturdy, round steel shaft with rust-protective finish: double nickel and subsequent matt-finished chrome-plating.

Sturdy, round steel shaft with rust-protective finish: double nickel and subsequent matt-finished chrome-plating.

Piece by piece calibration and final inspection. With permanent laser-marked serial number identifying the product.

Piece by piece calibration and final inspection. With permanent laser-marked serial number identifying the product.

Clearly legible analogue display for simple pre-selection of the desired torque.

Clearly legible analogue display for simple pre-selection of the desired torque.

Ergonomically shaped handle allows for automatically gripping it in a centric position. Important for obtaining an exact release torque.

Ergonomically shaped handle allows for automatically gripping it in a centric position. Important for obtaining an exact release torque.

Additional micro-scale for fine adjustment.

Additional micro-scale for fine adjustment.

Simple pre-setting of the torque by turning the knurled ring at the end of the handle, fixing it by sliding it into position.

Simple pre-setting of the torque by turning the knurled ring at the end of the handle, fixing it by sliding it into position.

For repairs of small trucks, transporters and tractors. With 3/4" square drive (19mm). Ratchet mechanism with reversing lever for clockwise and anticlockwise rotation. Sturdy steel shaft with rust-protective finish: double nickel and subsequent mattfinished chrome-plating. Piece by piece calibration and final inspection (including test certificate). Tolerance according to ISO 6789: +/- 3%. Clearly legible analogue display with additional micro-scale for fine adjustment. Total length 820mm. Packaged in a practical plastic storage box.

Click here for more information

NO 23 340

MicroClick torque wrenches are precision tools. They are packaged in a sturdy and practical plastic storage box.

- Reverse lever for clockwise and anticlockwise rotation.

- Sturdy, round steel shaft with rust-protective finish: double nickel and subsequent matt-finished chrome-plating.

- Piece by piece calibration and final inspection. With permanent laser-marked serial number identifying the product.

- Clearly legible analogue display for simple pre-selection of the desired torque.

- Ergonomically shaped handle allows for automatically gripping it in a centric position. Important for obtaining an exact release torque.

- Additional micro-scale for fine adjustment.

- Simple pre-setting of the torque by turning the knurled ring at the end of the handle, fixing it by sliding it into position.