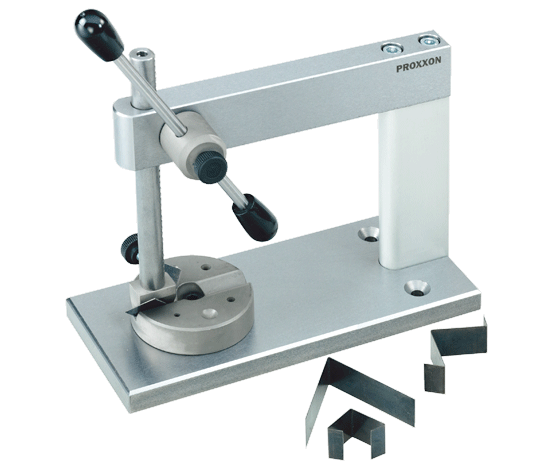

MICRO press MP 120

Pressing in, pressing out, riveting, imprinting, edging, bending of wires and sheets. Embossing, beading and crimping of easy to form materials.

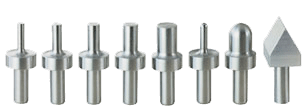

With 5 cylindrical pressing tools (surface hardened) being inserted into the toothed rack and fixed with a knurled screw: Ø 3 - 4 - 5 - 6 and 8mm. One each semi-spherical profile Ø 3 and Ø 9mm as well as a 60° square prism for bending sheet metal. The counterpart is an easily adjustable, hardened revolving plate with all required holes and bottom dies for the above-specified pressing tools.

Toothed rack at one front end with 6mm bore for use of the 8 bottom dies for the above-specified pressing tools. 5mm bore at the other front end for use of all commercially available riveting tools: simply wind up the toothed rack, take it out and reinsert it upside down.

Force of pressure approx. 1,000N (100kg). Maximum stroke of toothed rack with inserted tool 65mm, above revolving plate 50mm. Solid steel arm with 120mm throat. Ground base plate of steel, 80 x 190mm with an 8mm centre and two fastening bores. Weight approx. 2,800g.

NO 27 200

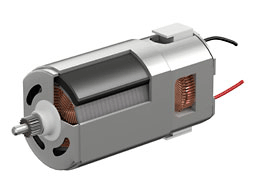

A comparatively more expensive direct current (DC) special motor with permanent magnet technology.

A comparatively more expensive direct current (DC) special motor with permanent magnet technology.